From giant manufacturing plants to modern assembly lines, programmable logic controllers (PLCs) are the unsung heroes of industrial automation.

Among the leading brands in the PLC world, Allen Bradley stands tall, with a history of innovation and quality that’s as dependable as it is vast.

For engineers and technicians navigating the complex world of industrial automation, understanding the types of Allen Bradley PLCs available is essential to implementing efficient and robust control systems.

This in-depth guide will dissect Allen Bradley’s primary PLC series, from their applications to selection criteria, to equip professionals with the knowledge needed to choose the right PLC for their specific requirements.

Whether you’re a seasoned automation expert or setting your first foot on the ladder of control engineering, this comprehensive overview will demystify the world of Allen Bradley’s PLC offerings.

PLC Basics

Before we plunge into the specifics of Allen Bradley’s PLC lineup, it’s crucial to comprehend the role of PLCs in the industrial context.

Think of PLCs as the brains behind the brawn of machinery and equipment in complex manufacturing processes.

These robust industrial computers execute programming logic for process control, human-machine interfacing, and data acquisition, making them indispensable in maintaining precision and efficiency within critical operations.

PLCs enable automation by monitoring inputs from sensors and switches, making decisions based on programmed instructions, and delivering outputs to control various industrial processes.

PLCs come in a wide range of sizes and capabilities, varying from simple controllers with limited I/O (input/output) points to high-end modular systems with extensive networking capabilities. Allen Bradley’s PLC series caters to different levels of automation needs, with each series having its own unique features and functionalities.

Popular Allen Bradley PLC Series

Allen Bradley offers a range of PLC series, each tailored to different application sizes and industry niches. Understanding the distinctions between these series is the first step in determining which one aligns with your project’s demands. Here are some of the most popular PLC series from Allen Bradley:

MicroLogix Series

The MicroLogix family is Allen Bradley’s compact, low-cost PLC range, ideal for small to mid-sized applications.

It’s known for its ease of use and versatility, making it a favorite among those integrating automation in less complex systems. Some key features of the Micro800 series include:

- Support for up to 132 I/O points

- Built-in Ethernet and serial ports for easy connectivity

- User-friendly programming software, CCW (Connected Components Workbench)

- Ability to expand with plug-in modules for increased I/O capabilities

CompactLogix Series

Sitting in the mid-range, the CompactLogix series provides a balance of performance and scalability. These PLCs support multiple I/O modules and offer communication flexibility, accommodating various industrial networking requirements. The CompactLogix series features:

- Support for up to 30 local I/O modules

- Compatibility with various communication protocols, including Ethernet/IP and DeviceNet

- Built-in motion control capabilities

- Flexible programming options such as ladder logic, structured text, and function block diagramming

ControlLogix Series

At the top end, the ControlLogix series delivers power, modularity, and high-performance capabilities suitable for the most complex and demanding automation systems.

Their distributed control system (DCS) compatibility and extensive redundancy options are renowned in the industry. Here are some key features of the ControlLogix series:

- Support for up to 128 local I/O modules and thousands of distributed I/O points

- Redundancy options, including redundant controllers and power supplies, for increased system reliability

- Advanced motion control capabilities with integrated servo drives and motors

- Compatibility with various programming languages, including structured text, sequential function charts, and instructions list

- Compatibility with third-party devices through a variety of communication protocols, including EtherNet/IP and ControlNet

Despite their differences, all three series share the same software development environment – Connected Components Workbench (CCW).

This user-friendly programming software offers a common platform for all CompactLogix and ControlLogix PLCs, making it easier to develop and maintain automation projects.

Features and Applications

Each Allen Bradley PLC series contains a distinct set of features that cater to different industrial needs and applications. Some key features and applications of these PLCs are discussed below.

MicroLogix Series

The MicroLogix series is ideal for small-scale operations, such as stand-alone machines or simple process control. Its compact size, low cost, and easy programming make it a popular choice among system integrators and machine builders. Here are some common applications of the MicroLogix series:

- Basic machine control, such as packaging and material handling

- Simple process control, such as batching and temperature control

- Small-scale data acquisition and monitoring systems

CompactLogix Series

The CompactLogix series is designed for mid-range applications that require more flexibility and scalability. It offers a wider range of I/O options, advanced communication capabilities, and the ability to handle larger amounts of data. Some typical applications of the CompactLogix series include:

- Multi-axis motion control

- Complex process control with high-speed sequencing and precision

- Data-intensive applications, such as SCADA systems and remote monitoring.

ControlLogix Series

The ControlLogix series is the most powerful and versatile PLC family from Allen Bradley. It is designed for large-scale and complex operations that require high-performance and reliability. With its advanced features, the ControlLogix series can handle demanding applications in various industries, such as:

- High-speed production lines in manufacturing

- Sophisticated process control in oil and gas, chemical, and pharmaceutical industries

- Plant-wide automation systems with multiple controllers.

Industries Specific Applications

A single musical composition can elicit various emotions based on its surroundings; likewise, the utilization of Allen Bradley PLCs differs among different sectors, each contributing its distinct melody to the industrial landscape.

Manufacturing

ControlLogix in the manufacturing industry orchestrates the production line with its precision, ensuring just-in-time manufacturing and throughput efficiency.

Oil and Gas

The rigorous environment of oil and gas operations requires the robustness and resilience of Allen Bradley CompactLogix to keep the show running even in the harshest conditions.

Automotive

MicroLogix may be the score that the automotive industry needs for its local operations, where efficiency is combined with the nuances of customized control systems.

Selection Criteria

When it comes to selecting the right PLC for your project, there are several key factors to keep in mind. These include:

Performance and Power

Assess the computational performance and power of the PLC to ensure it’s capable of handling your application’s processes without strain.

Consider factors such as processing speed, I/O capacity, and memory capacity.

Flexibility and Scalability

Choose a PLC that offers flexibility and scalability to accommodate future expansion or changes in your application.

Look for features like expandable I/O modules, communication options, and software compatibility. This will save you time and money in the long run.

Reliability and Durability

PLCs are often used in harsh industrial environments, so it’s essential to consider their reliability and durability.

Look for PLCs with high-quality components, protective enclosures, and certifications for extreme conditions.

Programming Options

PLCs can be programmed using various methods, including ladder logic, structured text, and function block diagrams.

Consider the programming options available and choose one that aligns with your team’s skills and preferences.

Support and Maintenance

Choose a PLC from a reputable manufacturer with a reliable support system in place. This will ensure any issues are quickly resolved, minimizing

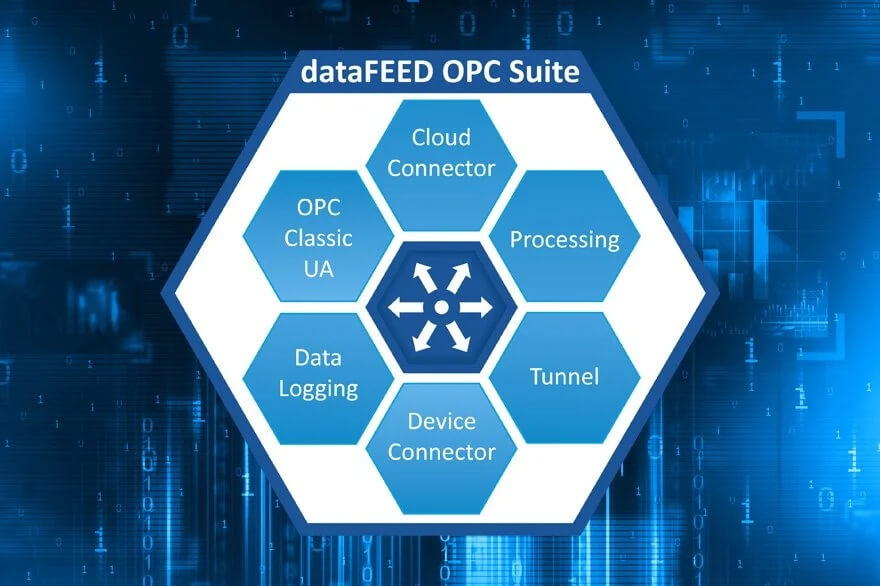

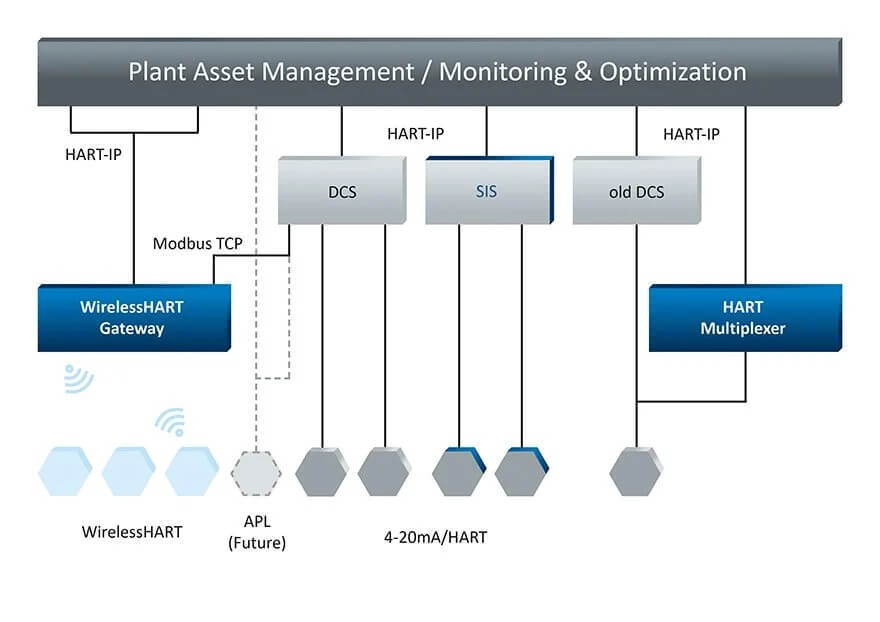

Communication Capabilities

Evaluate the communication capabilities of the PLC, including wired and wireless options, to ensure it can easily integrate with your existing systems.

Look for features like Ethernet ports, serial communication, and industrial protocols.

I/O Count and Types

Consider the input/output requirements of your application. Does it need digital, analog, or specialty I/O? How many points are needed for each type?

Networking and Communication

The ability of a PLC to integrate into existing systems through various networking protocols is critical. Evaluate communication options like Ethernet/IP, DeviceNet, and serial connections to ensure compatibility.

Physical Environment

Choose a PLC that can withstand the environmental conditions of the installation site, whether that means extreme temperatures or exposure to dust, moisture, or vibration.

Software and Programming

Evaluate the software that accompanies the PLC for programming ease and the availability of advanced features like simulation and troubleshooting tools.

Cost

Finally, consider the cost of the PLC and its accessories, including software licenses and I/O modules.

Make sure to factor in not only the initial purchase cost but also maintenance and upgrades over the lifetime of the PLC.

Comparison and Recommendations

To provide a comprehensive comparison, we will highlight the strengths and weaknesses of each Allen Bradley PLC series.

MicroLogix Series

Pros:

- Affordable entry point into automation systems

- Easier learning curve and user-friendly software

- Compact size and location flexibility

Cons:

- Limited processing power and I/O capability

- Less scalability for future expansion compared to larger series

- Not suitable for high-speed or complex operations

Recommended For: Start-ups or small businesses dipping their toes into automation, or for specialty tasks within larger systems where local decision-making or control is required.

CompactLogix Series

Pros:

- Enhanced performance and expandability compared to Micro800

- Flexibility in communication and networking options

- Ability to handle more sophisticated applications

Cons:

- Higher upfront cost

- Complexity may require more experienced personnel

- Not always necessary for applications that could fall within the capabilities of Micro800

Recommended For: Mid-sized companies or projects that require a balance between performance and cost.

ControlLogix Series

Pros:

- Unmatched performance, redundancy, and expandability

- Suitable for the most complex automation tasks

- Aligns with the highest industry standards and expectations

Cons:

- Significant investment required

- Over-engineered for smaller systems or operations not requiring such high specifications

- Steeper learning curve for newcomers to PLC programming and operation

Recommended For: Large-scale applications or critical processes where uptime, reliability, and expandability are non-negotiable.

Conclusion

Selecting an Allen Bradley PLC is more than just a choice of hardware; it’s about investing in the sustainability and efficiency of your industrial operation.

By understanding the scope of each series and matching their capabilities to the unique demands of your application, you can ensure a seamless integration that brings value both in the short and long term.

To reiterate, your selection process should involve a thorough assessment of the performance, I/O, networking, and environmental factors specific to your project’s needs.

In doing so, you not only harness the power of automation but also the reputation of Allen Bradley’s commitment to quality and innovation.

Whether you opt for the entry-level Micro800, the versatile CompactLogix, or the powerhouse ControlLogix, remember that the right choice of PLC is the foundation upon which you build the future success of your industrial automation system.

Now equipped with this guide, take the next step with confidence and precision — just as an Allen Bradley PLC would.