HART-IP in the Process Industry: Bridging the Gap

4 July, 2024

Share this story

In today’s competitive industrial landscape, the need for seamless and efficient communication within process industries is more critical than ever.

Greenpeg, a leader in industrial distribution, has partnered with Softing to bring innovative solutions like HART-IP to the forefront.

This article explores how HART-IP can bridge the gap in industrial communication, offering a reliable and versatile solution for process industries.

It combines the simplicity of HART with the speed and versatility of Ethernet, providing a powerful solution for modern industrial applications.

We provide comprehensive training and support to ensure smooth implementation and maximum return on investment.

Moreover, we emphasize the importance of leveraging data-driven insights to optimize operations.

By utilizing HART-IP, industries can gain valuable insights into their processes, identify inefficiencies, and implement corrective actions promptly.

By adopting HART-IP, process industries can achieve enhanced data accessibility, simplified integration, and future-proof communication networks.

Greenpeg, in partnership with Softing, is committed to delivering innovative solutions that drive efficiency and productivity.

For more information on implementing HART-IP in your operations, reach out to us. We’re here to support you every step of the way.

Greenpeg, a leader in industrial distribution, has partnered with Softing to bring innovative solutions like HART-IP to the forefront.

This article explores how HART-IP can bridge the gap in industrial communication, offering a reliable and versatile solution for process industries.

What is HART-IP?

HART-IP is an IP-based version of the HART (Highway Addressable Remote Transducer) protocol, designed to facilitate communication between field devices and control systems over Ethernet networks.It combines the simplicity of HART with the speed and versatility of Ethernet, providing a powerful solution for modern industrial applications.

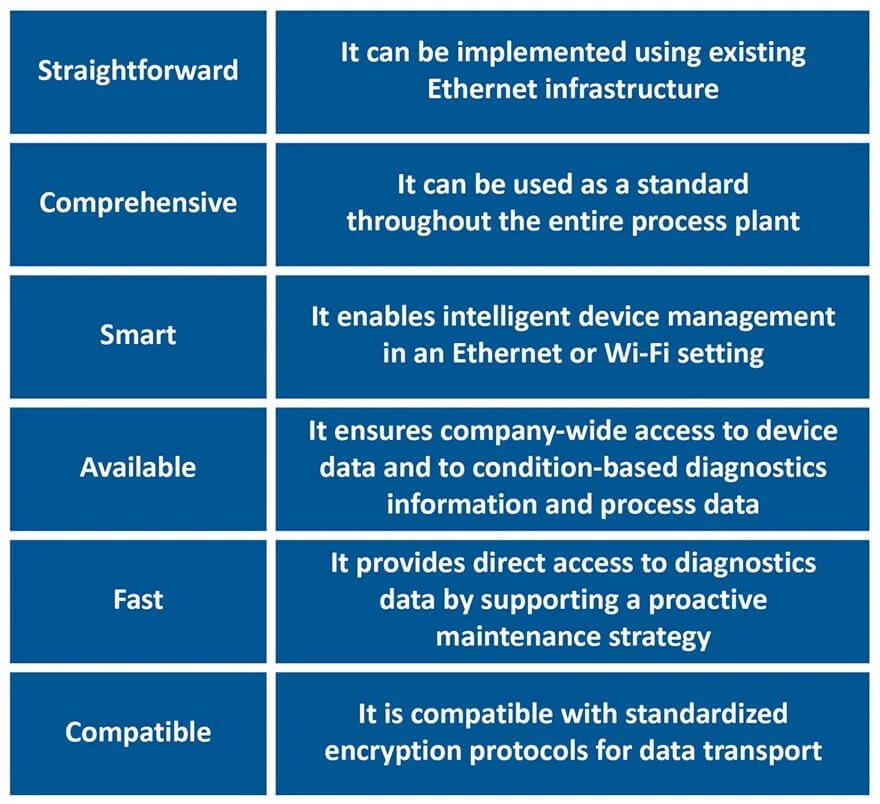

Key Advantages of HART-IP

1. Enhanced Data Accessibility

HART-IP allows for the direct transmission of digital data from field devices to control systems, facilitating real-time data access and improved decision-making.2. Simplified Integration

With HART-IP, integrating field devices into existing Ethernet networks becomes straightforward. This reduces the complexity and cost associated with network expansion.3. Future-Proof Solution

HART-IP is designed to be compatible with future advancements in Ethernet technology, ensuring long-term viability and scalability.

Implementing HART-IP in Process Industries

1. Upgrading Existing Networks

For industries already using HART-enabled devices, upgrading to HART-IP can be a seamless process. Softing’s HART Interface Cards enable easy integration, providing a direct connection between field devices and Ethernet networks.2. New Installations

For new industrial setups, implementing HART-IP from the outset ensures a robust and scalable communication network. Solutions like Softing’s dataFEED OPC Suite offer comprehensive support for HART-IP, ensuring reliable data exchange and network stability.

3. Real-time Monitoring

Tools like Softing’s TH LINK HART provide real-time monitoring and diagnostics, ensuring optimal performance and quick fault resolution. This is crucial for maintaining continuous and efficient operations in process industries.Greenpeg's Value Addition

At Greenpeg, we understand that each industrial setup has unique requirements. Our team of experts works closely with clients to tailor HART-IP solutions that meet their specific needs.We provide comprehensive training and support to ensure smooth implementation and maximum return on investment.

Moreover, we emphasize the importance of leveraging data-driven insights to optimize operations.

By utilizing HART-IP, industries can gain valuable insights into their processes, identify inefficiencies, and implement corrective actions promptly.

Conclusion

HART-IP represents a significant advancement in industrial communication, bridging the gap between field devices and control systems.By adopting HART-IP, process industries can achieve enhanced data accessibility, simplified integration, and future-proof communication networks.

Greenpeg, in partnership with Softing, is committed to delivering innovative solutions that drive efficiency and productivity.

For more information on implementing HART-IP in your operations, reach out to us. We’re here to support you every step of the way.