Enhance Your Brewing Process with Our Advanced Yeast Monitoring System

24 July, 2024

Share this story

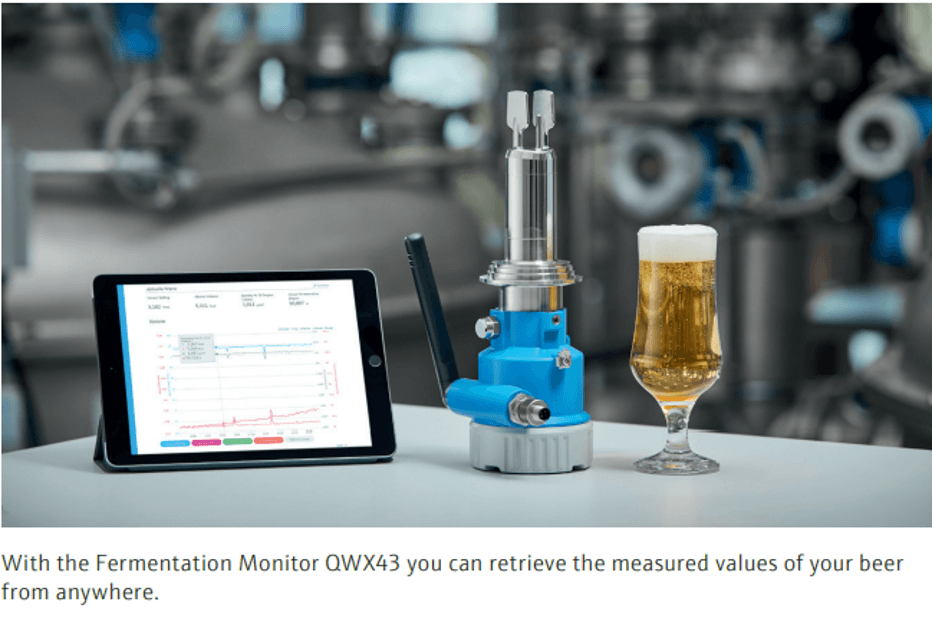

We are excited to introduce an innovative solution to streamline and optimize your brewing process: the Fermentation Monitor QWX43.

Designed to provide precise, real-time monitoring of all key fermentation parameters, this advanced system ensures that you achieve the highest quality in every batch of beer.

Why Choose the Fermentation Monitor QWX43?

Comprehensive Real-Time Monitoring

The Fermentation Monitor QWX43 continuously tracks all crucial parameters of your fermentation process. This multi-sensor system delivers accurate, real-time data that can be accessed anytime, anywhere, giving you full control over your brewing operations.

Improve Efficiency and Accuracy

Traditionally, measuring residual extract and other fermentation parameters requires manual sampling and laboratory analysis, which is both time-consuming and provides only selective results. With the QWX43, these measurements are automated, offering minute-by-minute updates that replace manual efforts, save time, and improve accuracy.Data-Driven Process Optimization

Our yeast monitoring system allows you to make data-driven decisions by comparing values from past batches and receiving automatic notifications. The system also automatically creates, saves, and downloads batch data, significantly reducing your documentation workload.